- Center for Research Computing Data

- Prospective Users

- Supported Research

- Computational Materials Science and Mechanics (CMSM) Group

Computational Materials Science and Mechanics (CMSM) Group

Principal Investigator: Iman Salehinia, Ph.D., Department of Mechanical Engineering.

Research in CMSM group is focused on two main areas:

-

Application of computational materials science in materials design and physical/mechanical behavior of nanomaterials and nanostructures.

Advances in energy- and defense-related technologies and aerospace engineering entail developing new classes of materials that can perform efficiently without premature failure under extreme loading and harsh environmental conditions. Research is focused on the mechanical and physical properties of nano-materials, and the design of advanced materials with targeted functionalities driven by predictive computational/theoretical multiscale methods. Multiscale computer modeling provides a strong basis for understanding the deformation mechanisms and behavior of materials across length scales. Models in smaller size-scales can be used to predict the behavior in larger size-scales. Experimental data are used to calibrate these computer models through extensive verifications of the simulation results and to guide them in a way that leads to tangible applications. The materials and structures of interest include metals, graphene, ceramics, carbon nanotubes, nano-fibers, nano-foams, and nano-wires.

-

Application of computational mechanics in conventional and advanced manufacturing methods.

Research is centered on the application of finite element method to explore the effects of the design parameters on the thermal/mechanical characteristics of the conventional manufacturing processes such as stamping, rolling, forging, and extrusion; and advanced manufacturing processes such as laser assisted machining, and in general, additive manufacturing. Durability of the tools with high tribological loads is also of interest in this research area. High pressures, high temperatures, and high relative slip between the contact surfaces of the tools and the deformed materials are common in manufacturing processes resulting in wear and change in shape.

Prospective user?

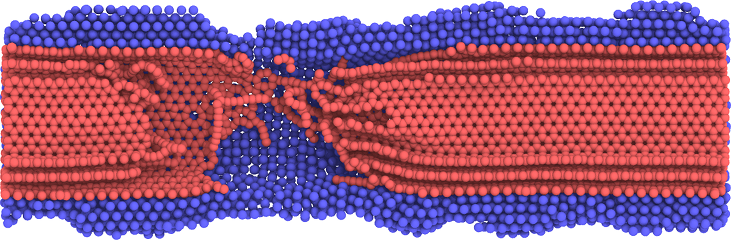

Metal Coated CNT Under Tensile Loading

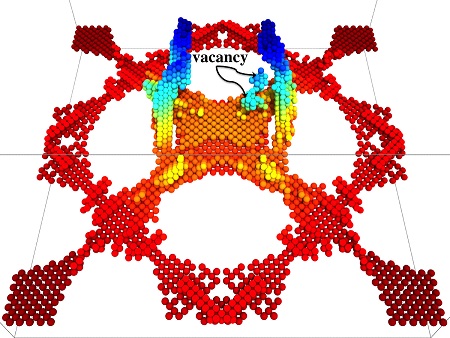

Dislocations Inside Niobium Layer in NbC/Nb Multilayer

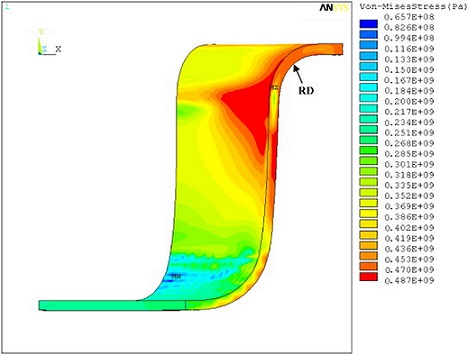

Von-Mises Stress for a Sheet in a Deep Drawing Process

-

For Prospective Users

-

Resources

-

Supported Research

- Critical Current by Design

- Image Reconstruction Software Using Proton Computed Tomography (pCT)

- Advanced-Accelerator Concepts

- Orphan Gene Project

- Computational Materials Science and Mechanics (CMSM) Group

- Vortex Pinning in Thin Superconducting Films and Strips

- High-Throughput Analysis of High-Content Biological Images

- High Precision Modeling of Ultracold Electron Sources

- Collisional Simulation Methods for Charged Particle Beam Dynamics and Applications

-

Getting Access

-

HPC Policies

-

Resources

- Resource Monitors